-

solutinos

-

Hire

Frontend Developer

Backend Developer

-

NodeJS Developer

-

Java Developer

-

Django Developer

-

Spring Boot Developer

-

Python Developer

-

Golang Developer

-

Ruby on Rails Developer

-

Laravel Developer

-

.NET Developer

Technology

-

Flutter Developer

-

React Native Developer

-

Xamarin Developer

-

Kotlin Developer

-

Cross-Platform Developer

-

Swift Developer

-

MongoDB Developer

-

C Developer

-

Smart Contract Developers

Cloud

-

-

Services

Mobile Development

Web Development

- Work

-

Multi Services App

-

Food Delivery App

-

Grocery Delivery App

-

Taxi Cab Booking App

-

Multi Services App

-

OTT Platform APP

-

Social Media APP

-

Freelance Service App

-

Car Rental App

-

Medicine Delivery App

-

Liquor Delivery App

-

Sports Betting App

-

Online Coupon App

-

eLearning App

-

Logistics & Transportation App

-

Courier Delivery App

-

On-Demand Real Estate App

-

E-Wallet APP

-

Online Dating App

-

Handyman Services App

-

-

Process

-

Company

Quick Summary : The logistics, transport and even electric mobility sector face numerous challenges like supply chain disruptions, vehicle breakdowns, rising fuel/battery costs, and regulatory compliance. However, automotive companies can overcome these obstacles using technological solutions like machine learning and artificial intelligence. With ML-powered predictive maintenance technologies, automotive organizations, logistics and freight companies, or even cab aggregators that deploy trucking and car fleets, can transition to proactive vehicle maintenance approaches.

The mobility sector has had its fair share of challenges. It was rampant with unexpected challenges like supply chain disruptions, rising costs, quality control issues, and regulatory compliance. However, over the last few decades, automotive companies have moved from zero automation to full automation, using tech solutions that have helped mitigate these challenges and turned them into opportunities. AI/ML, deep learning, and other technological advances have helped automotive organizations tackle these challenges head-on.

With the incorporation of predictive maintenance technologies, most of the challenges can be taken care of, and superior levels of efficiency can be achieved. Organizations are now seeing the potential possibilities that shifting from reactive to predictive maintenance for vehicles can bring for them and their customers.

Let’s see how machine learning development services are using the power of machine learning to help the automotive sector reap benefits.

What is Predictive Maintenance?

The core principle of Predictive maintenance for vehicles lies in getting pre-emptive signals about potential risks, failures, and issues that can arise in the future, and taking action to avoid them from happening. Predictive maintenance is a step forward from other methodologies of maintenance in the sense that it allows a time bracket to take actions before the concurrence of the actual event, which is unlike reactive maintenance where fixing is done after failure or preventive maintenance where schedules are made regardless of condition.

Predictive maintenance in the automotive sector is based on optimizing maintenance schedules based on real-time data, so that breakdowns can be prevented, thus being beneficial for the automakers and customers alike as it reduces downtime and costs.

Predictive Analysis Using Machine Learning in the Automotive Sector

Predictive maintenance uses machine learning algorithms, which is a subfield of artificial intelligence, where machines learn how to perform without using highly technical programming. In predictive maintenance analytics, the data from sensors, equipment logs, and other sources are analyzed and predictions are made about the vehicle. These predictions involve information about potential failures, help in remote diagnosis of issues, and save from potential breakdowns.

While logistics companies and trucking fleet giants like DHL, Maersk, etc. use ML for predicting vehicle failures, even aviation companies like Boeing, Alstom, etc. are using ML to predict engineer failures for their flights and train fleets.

Some of the best data analytics consulting services use statistical predictive maintenance where the historical maintenance data from high-end vehicle fleets are used to predict future events. Condition-based predictive maintenance services help monitor the overall health of the vehicle using real-time data so that maintenance decisions can be made accordingly.

The ML flow for Predictive Analysis: How does it work?

Sensors everywhere: Trucks, cars, and even complicated engines like that of ships, trains, and planes are fitted with sensors that constantly check things like temperature, pressure, vibrations, and how fast parts are spinning. These sensors are always working, sending information to the computer storage systems (the cloud) every few minutes or in real-time.

Now suppose a truck in a fleet of a logistics company breaks down. The company will check the sensor data hours, days, or weeks before the breakdown. The critical question is— what changed in the days or hours before it stopped working?

Now using such examples of past breakdowns and their sensor data, companies create a machine learning model that has learnt the patterns that happen before the vehicles break. Once trained, this smart system can look at current sensor data from working vehicles and alert about any potential breakdown that can happen. The system doesn't just predict problems; it also explains why it thinks something might break. For instance: The engine is vibrating more than usual, and the temperature is rising faster than normal."

Now, instead of waiting for maintenance periods or actual breakdown of vehicles, companies can fix potential problems early. In simple terms, ML algorithms are like having a super-smart mechanic who's always watching every part of every vehicle, using lessons from past breakdowns to prevent future ones.

How Machine Learning Powers Predictive Maintenance?

According to McKinsey’s associate partner Jan Paul Stein, the automotive sector has the potential to generate as much as one-third of sales from new products, powered by AI and machine learning (ML) technologies. Predictive maintenance for vehicles driven by ML enables automotive organizations to track historical maintenance data, mileage, and model, and helps monitor data from vehicle fleets.

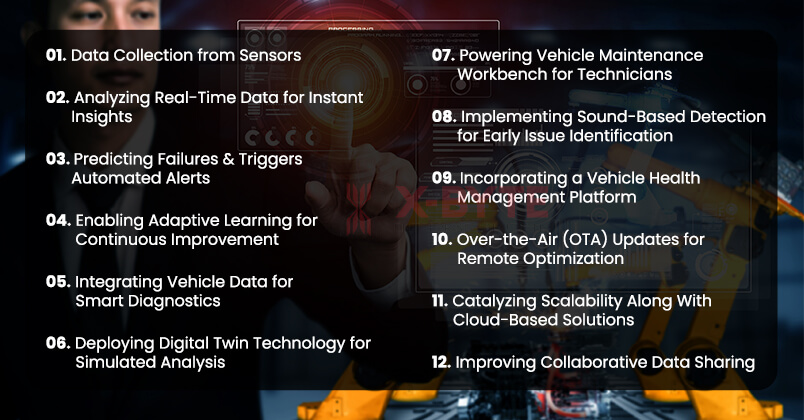

Here’s how ML algorithms have powered predictive maintenance in automotive:

Data Collection from Sensors

Data is an asset that often goes unnoticed in the bigger context. Machine Learning is based on using this data asset and making future-focussed predictions for the automotive. This is done through the sensors placed in vehicles which do the work of continuously collecting information about critical parameters like engine performance, temperature, vibrations, etc. Data analytics consulting service providers use this data to serve as the base for the ML algorithms to detect patterns and identify early warning signs of potential failures.

Analyzing Real-Time Data for Instant Insights

A huge part of automotive predictive maintenance also relies on using past data and comparing it with real-time data from the vehicles. ML algorithms make this tracking process easier, detect discrepancies between current data and records, and analyze them to foresee potential risks. This is done by processing real-time data from sensors, comparing it with historical data, and flagging it, enabling proactive and predictive car maintenance rather than reactive fixes.

Predicting Failures & Triggers Automated Alerts

Post-failure work is often cumbersome on the purse for automakers and customers alike. With analysis-based prediction future failure recognition becomes easier and timely alerts can be provided to drivers or fleet managers, allowing them to schedule maintenance before a practical breakdown occurs.

Enabling Adaptive Learning for Continuous Improvement

Machine learning is an iterative and closed-loop process that gives refined results and predictions, as ML algorithms get better with time as they keep learning from each new available data. So, more data means more input for analysis, better results, and recognition of faults. AI-based machines also can detect defects 90 percent more accurately than humans. This also acts as a premise to reduce false alarms and improves overall vehicle accuracy.

Integrating Vehicle Data for Smart Diagnostics

A point of contention for automakers has always been the issues arising out of a lack of clarity on the exact factor that’s causing problems in the vehicles. With the incorporation of ML models, the analysis of sensor data becomes incredibly accurate and exact issues can be pinpointed, rather than relying on general error codes. This takes off a huge load from automakers as it reduces guesswork and ensures that mechanics address the root cause of the problem rather than just its symptoms.

Want advanced predictive maintenance and smart diagnostics solutions for your vehicle fleets?

Deploying Digital Twin Technology for Simulated Analysis

Digital Twins have changed the way processes in the automaking sector are visualized. A digital twin, the virtual replica of the vehicle, mirrors its real-world condition, and the ML analyzes the real-time data and feeds it back to the Digital Twin. The predictive maintenance for cars is based on synergy between ML and digital twins, empowering manufacturers and maintenance teams to simulate and predict issues before they affect the actual car. The acceptance by the automotive sector towards powering digital twins through ML can be gauged from the data by McKinsey, where respondents said that they were 1.6 times more likely to use AI/ML-based simulations for improving efficiency.

Powering Vehicle Maintenance Workbench for Technicians

Machine learning development services help develop a vehicle maintenance workbench powered by ML that offers mechanics an advanced dashboard with predictive insights. It highlights potential issues, suggests solutions, and even prioritizes repairs based on urgency, making vehicle servicing more efficient.

Implementing Sound-Based Detection for Early Issue Identification

ML has helped automotive companies detect early signs of mechanical failure, where any abnormality in engine noises, brake squeals, and other vehicle sounds are quickly compared with a database of known issues.

Incorporating a Vehicle Health Management Platform

Automakers have incorporated Vehicle Health Management Platforms that utilize ML to aggregate data from multiple sources. This provides a holistic view of a vehicle's condition and enables fleet operators and car owners to monitor multiple vehicles while keeping track of any possible failure situations across an entire fleet.

Over-the-Air (OTA) Updates for Remote Optimization

The remote software update capabilities of ML have changed the way vehicles perform. ML enables vehicles to receive smart software updates, eliminating the need for a visit to the service center. With ML-driven OTA updates, automotive organizations have added the benefits of improved performance, fixing minor issues, and enhanced security in real-time.

Catalyzing Scalability Along With Cloud-Based Solutions

Security is a primary concern when data over the network comes into play and ML-powered cloud platforms have added security to the mix by storing vehicle performance data securely. This data is then used to train better predictive models. Additionally, it ensures that the vehicles benefit from collective intelligence and improved maintenance strategies.

Improving Collaborative Data Sharing

It’s the era of collaboration and utilizing the capabilities of organizations to power a product or vehicle. ML models have allowed different manufacturers to collaborate and share data, which is used to analyze vehicle performance and better detect and prevent issues across different vehicle types and driving conditions.

Applications of ML-based Automotive Predictive Maintenance in Vehicles

Predictive maintenance using ML has a profound impact on the automotive sector and has several use cases which span from real-time vehicle health monitoring and preventive component replacement to fleet management optimization and enhanced warranty management.

Let’s look at some of these.

Fleet Management

Minimizing vehicle downtime and reducing operational costs have been the top concerns for automakers and customers. Thanks to predictive analysis using machine learning, automakers and fleet operators have been able to minimize vehicle downtime and reduce operational costs, where the power of AI and ML are used. Additionally, fleet managers can now detect potential failures early and schedule preventive maintenance through data provided by in-vehicle sensors in real time. Multiple factors like faults in air pressure systems, suspension, brake systems, electric power steering, etc. are analyzed and fleet reliability is ensured.

Passenger Vehicles

For private car owners, vehicle safety and convenience take center stage. Predictive maintenance solutions and AI-driven solutions use the data from vehicles and sound-based detection to monitor vehicle health, providing early warnings for faulty components, and making life easy for car owners. The biggest breakthrough has come in the form of Over-the-Air (OTA) updates where remote software improvements are made possible and the need for frequent service center visits is eliminated. ML gets data from sensors and finds possibilities of tyre wear, brake degradation, and sensor faults before they lead to costly repairs.

Electric and Autonomous Vehicles

Electric and autonomous vehicles have transformed mobility and made vehicles more than instruments of transportation. However, they need specialized predictive maintenance solutions, where continuous monitoring of battery degradation is necessary. Ml enables this by extracting health indicators from internal resistance data and detecting faults in regenerative braking systems, electric motors, and generators to ensure optimal performance. Technological improvements like digital twin technology and industrial IoT sensors have facilitated a reality where real-time virtual models of the vehicles can be used to achieve precise diagnostics, performance optimization, and component health.

Whether you're managing a large fleet or developing next-gen electric vehicles, fuel innovation with AI-driven Machine Learning!

Hire X-Byte for ML Development Services! Hire X-Byte for ML Development Services!Benefits of Machine Learning-led Automotive Predictive Maintenance

Machine learning has changed the way the automotive sector operates and added efficiency and productivity. AI and ML developments and deep neural networks have sped up the development of autonomous vehicles and redefined mobility. The benefits of ML for the automotive sector are enormous and machine-learning companies have made these possibilities a reality. Some of the benefits have been listed below.

Exponential Cost Savings

The core principle of automotive predictive maintenance solutions of detecting issues before they escalate has made it a must-have strategy for automotive companies. It has helped them with expensive repairs, minimizes vehicle downtime, and lowers maintenance costs. Fleet operators have been able to optimize service schedules, and prevent unnecessary part replacements and labor costs.

Accelerated Vehicle Performance

As machine learning allows the continuous monitoring and optimization of critical vehicle functions it enables smoother rides, better fuel efficiency, and long-lasting vehicles. Engine performance, transmission efficiency, exhaust systems, and structural stability are the key areas that ML algorithms help improve.

Improved Road Safety

Critical safety components like brakes, power steering, and suspension are all monitored through predictive analysis using machine learning. It helps prevent accidents caused by sudden mechanical failures and ensures safer driving conditions.

Lower Emissions with Environmental Benefits

Since the whole exercise of vehicle predictive maintenance is to ensure efficiency and productivity, the result is optimized vehicle performance, reduced fuel consumption, and lower emissions. A pre-emptied response helps in efficiently running engines, mining exhaust systems, and smooth transmission functions, resulting in a smaller carbon footprint.

Proactive Communication & Customer Satisfaction

Customer satisfaction is a prime driver of these technological developments in the automotive sector and predictive maintenance solutions allow OEMs, dealers, and fleet operators to proactively notify vehicle owners about potential issues. This acts as a key enabler of reduced unexpected breakdowns, enhanced service reliability, and improved customer satisfaction.

Increased Revenue for Manufacturers and Dealers

Predictive analysis using machine learning helps boost aftermarket sales of original spare parts, as it enables timely maintenance, thus proving to be a win-win for manufacturers, dealers, and customers. Additionally, it reduces warranty claims and costly product recalls.

Future of Predictive Maintenance in the Automotive Sector

Machine learning algorithms have been able to push the envelope for automakers and drive advancements in the automotive sector. There has been a design trend in the ML-powered predictive maintenance sector and it is being pushed as a strategy for adoption in personal and commercial vehicles.

Further, predictive maintenance companies enable the integration of AI-powered assistants and autonomous diagnostics. A future-centric approach for effectively incorporating predictive maintenance with ML solutions for automotive organizations rests on partnering with able machine learning development service providers.

The future of the automotive sector is in for a revamp with advancements in deep learning, cloud computing, and edge AI for even more accurate predictions and real-time monitoring.

X-Byte: Redefining Mobility With Machine Learning Expertise

X-Byte Enterprise Solutions provides predictive maintenance as a service, and machine learning consulting to change the way mobility is being perceived and realized in the current era. Works with some of the biggest names in the automotive sector and powered their automotive vision into reality with our machine learning development services. Our core strength lies in using data science and Machine Learning solutions to deliver exceptional vehicles of the future.