-

solutinos

-

Hire

Frontend Developer

Backend Developer

-

NodeJS Developer

-

Java Developer

-

Django Developer

-

Spring Boot Developer

-

Python Developer

-

Golang Developer

-

Ruby on Rails Developer

-

Laravel Developer

-

.NET Developer

Technology

-

Flutter Developer

-

React Native Developer

-

Xamarin Developer

-

Kotlin Developer

-

Cross-Platform Developer

-

Swift Developer

-

MongoDB Developer

-

C Developer

-

Smart Contract Developers

Cloud

-

-

Services

Mobile Development

Web Development

- Work

-

Multi Services App

-

Food Delivery App

-

Grocery Delivery App

-

Taxi Cab Booking App

-

Multi Services App

-

OTT Platform APP

-

Social Media APP

-

Freelance Service App

-

Car Rental App

-

Medicine Delivery App

-

Liquor Delivery App

-

Sports Betting App

-

Online Coupon App

-

eLearning App

-

Logistics & Transportation App

-

Courier Delivery App

-

On-Demand Real Estate App

-

E-Wallet APP

-

Online Dating App

-

Handyman Services App

-

-

Process

-

Company

Quick Summary : Inventory management software helps in transforming business operations and streamlining the processes. Explore the top 8benefits and features that should be added in an inventory management system by analyzing challenges and it’s potential solution to automate the business.

Inventory management is a crucial component of any company that deals with products, and the field encompasses manufacturing, retailing, and logistics. Effective inventory management entails getting the right stock in the right quantity at the right time at the right time at lesser costs and satisfying customers. However, handling the inventory manually or using conventional methods ultimately affects the accuracy, efficiency, and revenue that a company records.

This blog will give insight into Inventory Management Software (IMS), the new inventory management method. IMS automates the tracking, monitoring, and forecasting process, making business optimization possible. Basic problems like overstocking, stockouts, and poor productivity can be resolved by using the right software in businesses ranging from small businesses to large corporations.

What is an Inventory Management System?

An inventory management system is a platform used to manage and monitor inventory, enhance stock utilization efficiency, perform demand forecasting, minimize costs, and manage stock. This digital solution provides real-time information about stock availability to reduce inventory overstocking and stockouts. With optimized inventory tracking software, businesses can ensure improved efficiency and productivity.

Do you Know?

- Figures from the IBEF show that retail electronic commerce in India achieved a major milestone, touching a GMV of USD 60 billion for fiscal year 2023, up 22% from fiscal year 2021-22.

- The global inventory management software market was USD 2.13 billion in the year 2023.

- The current market for non-invasive cosmetic surgery was USD 2.31 billion in 2024 and is expected to reach USD 4.84 billion by 2032, at a CAGR of 9.7 % in the forecast period from 2024 to 2032.

- Inventory management software makes inventory management more efficient, frees up time for tasks involved in tracking inventory accurately, manages inventory reordering, and alerts the accounting function when inventory levels require attention.

- Large organizations also employ this software to reduce incidents of excessive stock.

- Moreover, the future trend towards automating warehouses for inventory management will cause increased demand for inventory management systems.

- Global market share has been boosted on this parameter. Zebra Technologies survey found that as many as 87 percent of industrial decision-makers are either adding or planning to extend warehouse space by 2024.

Transform the inventory management process with advanced solutions!

Connect with Experts Connect with ExpertsBenefits of Inventory Management Software

Inventory management system helps businesses save money and ensure real-time stock monitoring and integrating this software into your business, you would be able to:

Enhanced Accuracy

The inventory tracking software assists in improving the management process to ensure optimal availability. Inventory tracking and management have become crucial for diverse retail businesses requiring real-time monitoring for better accuracy.

Cost Reduction

By tracking real-time inventory availability and demand, various businesses can avoid overstocking and enhance warehouse management. The advanced solution helps manage perishable items by monitoring expiry to ensure products are sold before expiry. This reduces wastage and ensures optimized inventory procurement based on historical data to avoid unnecessary expenses.

Better Inventory Control

An optimized inventory management system helps in real-time inventory tracking to get constant updates on stock levels. This helps track stock availability, reordering requirements, and demand for a specific product. The advanced solutions also help categorize and label inventory to easily locate it in the warehouse to ensure streamlined operations.

Automation

Tracking the inventory levels manually can be time-consuming and lead to human error. The integrated platform provides real-time stock updates after sale, purchase, or movement. It also provides alerts based on a set threshold. This ensures the availability of the inventory to fulfill the customer requirements with reliable inventory management. It helps ensure order fulfillment, preventing customers from receiving incorrect or delayed items.

Boosted Customer Satisfaction

With an inventory management and tracking solution, businesses can easily maintain stock levels to fulfill customer orders on time and provide better service quality. This helps maintain the most demanding stock to reduce stockouts. An interactive system helps maintain accurate stock, allowing businesses to provide exact delivery details to customers.

Data-driven Insights

Using historical data and trends to predict future demand ensures smooth demand forecasting. An automated stock management system also provides detailed information and reports on product selling, demand, and which products perform poorly.

This helps businesses create enhanced marketing strategies to boost performance. It also tracks supplier reliability by smoothly analyzing delivery times and order accuracy.

Scalability and Integration

growing businesses, scalable inventory management software can handle increased inventory, diverse locations, and higher transaction volumes. Using a centralized platform helps manage stock across multiple warehouses and stores. This platform also helps integrate accounting, sales, and e-commerce solutions to ensure smooth operations and workflow.

Improved Efficiency and Productivity

Establish automated inventory tracking solutions to streamline and optimize business processes. The digital solution helps manage retail businesses and boost productivity by tracking routine activities. By integrating with the production line, it also helps reduce downtime.

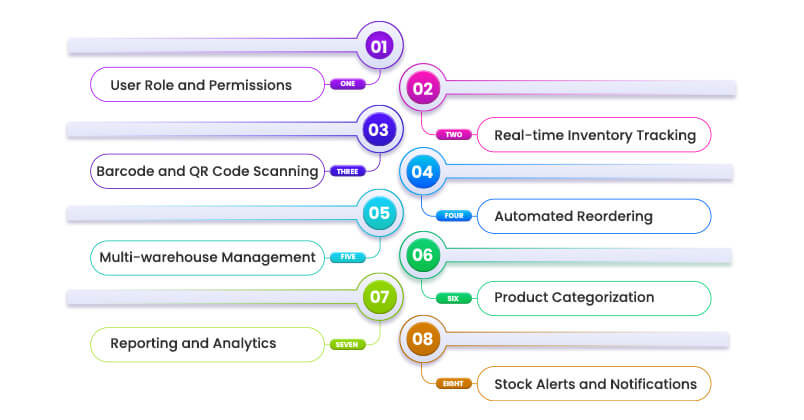

Key Features of Inventory Management Software

Implementing diverse features to boost productivity and efficiency creates inventory management systems. Businesses can use this software to streamline and optimize inventory tracking and management processes.

User Role and Permissions

Admins can assign role-based access to employees in the inventory management app. This helps enhance data security by restricting sensitive information and improving accountability by tracking user actions.

Real-time Inventory Tracking

The custom software is integrated with real-time inventory management and tracking transactions, orders, inventory status, reordering, and market performance. This prevents stockouts and overstocking and allows accurate data to be received to enable smooth decision-making.

Elevate the user experience by implementing high performing inventory management systems!

Barcode and QR Code Scanning

To keep track of the inventory, products are tagged with barcodes or QR codes and handheld scanners. This speeds up the stock tracking, counting, picking, and restocking processes, reducing human errors during inventory updates and ensuring timely reordering.

Automated Reordering

Retail businesses can set a reorder point and limit inventory level on when to reorder. When stock levels drop below the threshold, the software triggers a reorder or sends an alert.

Multi-warehouse Management

This feature allows businesses to establish centralized stock management of multiple warehouses and locations. It provides enhanced visibility to inventory levels across different locations. Ultimately, this simplifies inter-warehouse transfers and avoids duplication of inventory.

Product Categorization

It is crucial to group the items into diverse categories like type, size, brand, expiry date, and quantity. This helps in inventory searches and reporting and ensures smooth and streamlined inventory management.

Reporting and Analytics

Integrating smart reporting and analytics provides detailed insights into inventory performance through dashboards and customizable reports. It helps identify top-performing and underperforming products, ultimately improving purchasing decisions and inventory strategies.

Stock Alerts and Notifications

The system sends alerts for specific scenarios, like low stock, overstock, or upcoming expiry dates. This helps prevent losses due to expired or unsold inventory and ensures timely restocking activities.

Inventory management software with the features mentioned above helps businesses in various ways:

- Reduce operational costs by preventing overstocking or stockouts.

- Improve efficiency through automation and integration.

- Enhance customer satisfaction with accurate order fulfillment.

- Make data-driven decisions for long-term growth.

How to Select the Right Inventory Management System

Selecting the right inventory management system (IMS) is an important decision that impacts efficiency, costs, and overall business performance.

Analyze your Inventory Needs

It is essential to keep track of inventory and ensure easy accessibility and scalability of the solution. This also involves determining the type of inventory, such as perishable, seasonal, or located across multiple warehouses. An inventory management platform should be capable of tracking inventory levels, stock replenishment, and barcode scanning.

Integration Requirements

Analyzing the integration requirements will boost the inventory management system's performance. This platform can be integrated with other systems, such as accounting software for streamlined financial management, CRM platforms to align inventory with customer demands, and e-commerce platforms to ensure seamless inventory updates for online stores. It is also important to analyze whether the system offers APIs for custom integrations.

Scalability and Flexibility

Businesses can select the system that can be expanded with a growing business. It is also essential to ensure its ability to manage increased inventory or additional warehouses. This system should adapt to changing business processes or industry-specific needs.

User Experience and Training

It is necessary to ensure that inventory tracking and management systems have user-friendly and intuitive platforms that boost the user experience. It is also important to ensure that service providers offer comprehensive onboarding and ongoing assistance.

Cost and ROI Analysis

Businesses should understand and analyze software licensing fees, hardware requirements, and implementation costs. They should include system updates, customer support, and future upgrade expenses. They can also estimate ROI and evaluate potential productivity gains and cost savings to justify the investment.

Reliability and Security

Businesses should also analyze the vendor’s uptime guarantee to ensure the system is reliable and minimizes downtime. It is equally considered as crucial to confirm compliance with data protection regulations and inquire about encryption, backups, and disaster recovery plans.

Vendor Reputation

Analyze the feedback from other users to determine the satisfaction and performance. Businesses should also assess the vendor’s responsiveness and availability for support inquiries.

Future Proofing

Ensuring the system can adapt to your evolving business needs and industry standards is essential. To stay updated with market trends, an inventory management and tracking system should align with emerging technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT).

Challenges of Inventory Management with Solutions

Implementing inventory management software transforms these challenges into opportunities. It ensures accurate tracking, optimizes stock levels, improves efficiency, and supports data-driven decision-making. Businesses can save time, reduce costs, and enhance customer satisfaction, leading to market growth.

Inaccurate Inventory Tracking

Tracking and analyzing inventory with manual processes leads to errors and inaccuracy. On the other hand, not keeping track of real-time inventory records results in overstocking or stockouts.

Solutions:

- Implementing automated tracking systems with real-time updates to ensure data accuracy.

- Advanced technologies like barcode scanning and RFID technology minimize human error.

Inefficient Warehouse Management

When any system is integrated into the business, efficient organization leads to delays in locating and dispatching items. This inefficiency increases labor costs and reduces productivity.

Solutions:

- Warehouse management modules help in optimizing storage layouts and inventory tracking.

- Advanced features boost business operations, including picking path optimization and inventory location tracking.

Demand Forecasting

When manual tracking is done, it becomes hard to predict demand; if it is done, it can be prone to errors. Seasonal and unexpected demand becomes hard to manage.

Solutions:

- AI-powered forecasting tools help in analyzing historical data and trends.

- Predictive analytics help businesses to predict demand fluctuations.

Get access to feature-rich inventory management and tracking software to streamline business operations.

Hire Expert Developers CHire Expert DevelopersLack of Real-time Data Access

Data that is not accessible in real time can lead to an inefficient decision-making process and prevent employees from seeing current stock levels.

Solutions:

- Cloud-based systems enable real-time access to inventory data from anywhere.

- Mobile apps provide real-time updates for field teams.

Lack of Integration with Other Business Functions

When there are not integrated systems for all the purposes and businesses are maintaining separate systems for sales, accounting, and inventory, it causes inefficiencies. This data silos lead to miscommunication and errors.

Solutions:

- Integration with accounting, CRM, and e-commerce platforms ensures seamless data flow.

- APIs enable custom integrations tailored to business needs.

Conclusion

Inventory management software is an essential tool for transforming modern businesses. This streamlined system helps automate business operations, reduce costs, and improve customer satisfaction. It also addresses diverse business challenges by automating manual tasks, providing real-time data, and integrating with other business systems.

Choosing the right software ensures your business can maintain optimal stock levels, enhance warehouse management, and adapt to growth or changing market conditions. X-Byte Solutions provides high-tech solutions. By leveraging the latest technology, your organization can optimize its supply chain, reduce waste, and focus on delivering value to customers.

Frequently Asked Questions

-

What Are the Key Features of Inventory

Management Software?

- Real-Time Inventory Tracking

- Demand Forecasting

- Multi-location Management

- Order and Reorder Management

- Batch and Serial Number Tracking

- Integration with Other Systems

- Analytics and Reporting

- User-friendly Interface

-

How Can Inventory Management Software Help

Reduce Costs?

- Eliminates Overstocking and Stockouts

- Minimizes Storage Costs

- Reduces Labor Costs

- Prevents Losses

- Improves Supply Chain Efficiency

-

How Can Inventory Management Software Reduce Cost?

- Ensures Product Availability: Customers are likely to get products on time as the company has eliminated stock out incidences by addressing stock related issues.

- Faster Order Fulfillment: Processes of order fulfillment are accelerated by means of automated procedures and effective warehouse management.

- Error-Free Deliveries: Managing stock efficiently guarantees that correct merchandise is delivered, thus eliminating returns.

- Enhanced Transparency: Linking with other platforms that deals with business means keep updating the stock for the customers in real time which enhances trust and reliance.

- Personalized Experiences: Data utilization leads to improved demand planning to help organizations try to make better predictions of customer’s demands.

-

How can I choose the right inventory Management Software for My

Business?

- Assess Your Needs

- Consider Scalability

- Check Integration Capabilities

- Evaluate Features

- Compare Costs

- Seek Reviews and Demos

- Ensure Vendor Support

- Data Security and Compliance

By carefully evaluating these factors, you can select an inventory management software solution that meets your business's unique requirements and helps drive success.

-

How much does inventory management software cost?

An inventory management system can cost around around $50,000 to $99,999. The cost of the IMS can be dependent on several factors including tech stacks utilized, team size and expertise, portfolio of service providers, budget and timeline.

-

How can inventory management software improve customer

satisfaction?

- An optimized inventory management software helps in improving customer satisfaction by:

- Ensures product availability

- Faster order fulfillment

- Error-free deliveries

- Enhanced transparency

- Personalized experiences