-

solutinos

-

Hire

Frontend Developer

Backend Developer

-

NodeJS Developer

-

Java Developer

-

Django Developer

-

Spring Boot Developer

-

Python Developer

-

Golang Developer

-

Ruby on Rails Developer

-

Laravel Developer

-

.NET Developer

Technology

-

Flutter Developer

-

React Native Developer

-

Xamarin Developer

-

Kotlin Developer

-

Cross-Platform Developer

-

Swift Developer

-

MongoDB Developer

-

C Developer

-

Smart Contract Developers

Cloud

-

-

Services

Mobile Development

Web Development

- Work

-

Multi Services App

-

Food Delivery App

-

Grocery Delivery App

-

Taxi Cab Booking App

-

Multi Services App

-

OTT Platform APP

-

Social Media APP

-

Freelance Service App

-

Car Rental App

-

Medicine Delivery App

-

Liquor Delivery App

-

Sports Betting App

-

Online Coupon App

-

eLearning App

-

Logistics & Transportation App

-

Courier Delivery App

-

On-Demand Real Estate App

-

E-Wallet APP

-

Online Dating App

-

Handyman Services App

-

-

Process

-

Company

Quick Summary : AI is finding an expanded role in the manufacturing industry with widespread applications and trending use cases. The recent advancements in generative AI have been phenomenal and have provided the required boost for expedited adoption of artificial intelligence in the manufacturing industry. AI coupled with machine learning, computer vision, predictive analytics, robotics, etc. transforms core processes of manufacturing for higher efficiency and output.

Manufacturers have always been the earliest adopters and deployers of technology. The industry has never refrained from experimenting and upgrading. The same applies to the industry’s approach towards artificial intelligence. Efficiency, safety, quality, profitability, and sustainability are the core focus of manufacturing industry stalwarts when implementing AI in their processes and plant operations. While the industry already has advanced automation, analytics, robotics, sensors, and connectivity, what AI offers to the manufacturing sector is human-like ingenuity, adaptability, and decision-making.

The modest beginnings of AI in the manufacturing sector are now leaping to the next trajectory. With the advancements in Generative AI models, modesty has transitioned into highly sophisticated innovations. Today, AI has entered into mainstream manufacturing leaving no process in manufacturing that cannot be transformed by AI. The use cases and applications of AI in the manufacturing industry are far and wide, transforming core processes like never before.

This article details the implications of AI and its latest advancements in the manufacturing industry. The article explores various use cases and applications of AI-powered systems in various sectors of the manufacturing field.

Applications of Artificial Intelligence in Various Manufacturing Industry Sectors

AI-based algorithms process data from vibration sensors and other sources to detect anomalies, diagnose problems, and predict breakdowns. For instance, Bosch uses AI-based image recognition technology to detect defects in its automotive parts. This is done by training models for automated optical inspections using generative AI. “For a long time, associates in manufacturing checked parts for possible defects with the naked eye,” says Ria Reimer, project manager at Bosch.

Integrate AI Algorithms and enhance your manufacturing business!

Contact Our Team Contact Our TeamTextile Manufacturing

The integration of artificial intelligence (AI) in the textile and apparel manufacturing industry has various implications and use cases. AI-based tools with imaging tech help in assessing the material quality of fabrics (material grading). AI also reduces errors during inspection by detecting minor flaws (holes, stains, stitching issues) that compromise the fabric’s final quality or variation in quantity.

AI also automates bills of materials, sourcing, procurement processes, CPQs, etc. The AI-powered computer-aided design (CAD) system helps in pattern grading. AI-enabled sensors improve the precision of dye color matching, predict color fading, and reduce waste.

Electronics

AI-powered systems analyze data from sensors embedded in manufacturing equipment to predict when machines are likely to fail.

For instance, Schneider Electric, the French electronic manufacturing giant uses AI to collect and analyze datasets on weather patterns, and emissions to predict equipment failures and anticipate loads, This AI-enabled predictive analytics is leading a seismic shift in how Schneider Electric manages its energy systems for grid decarbonization and fighting climate change. AI also assists in designing electronic components by generating optimal designs. AI can predict the performance of semiconductor devices under various conditions, thus improving quality.

Glass Manufacturing

AI systems monitor and control the temperature and composition of glass during the manufacturing process to ensure consistent quality. Machine vision systems powered by AI detect imperfections in glass products, allowing for immediate corrective actions.

3B Fibre Glass, a leading manufacturer of glass fibers uses AI with deep-learning computer vision to monitor and analyze the fiber flow from bushings. The AI system identifies potential breakages 75 seconds in advance and alerts operators for quick intervention.

Food Manufacturing

In industries like Processed Food Manufacturing, AI can help with quality control through machine vision systems. These systems can be trained to identify contaminants in food raw materials like metal, plastic, adulterated objects, etc. AI algorithms can continuously monitor various food production stages using advanced imaging techniques to catch safety issues or any deviation in the color of food that suggests contamination.

As Wall Street Journal Reports: Companies like Pepsi and Colgate are upgrading their plants with AI sensors to ‘listen’ for machinery problems.

Pharma Manufacturing

AI in pharma manufacturing focuses on helping researchers cross-reference resources when developing new drugs, drug discovery, and clinical trials. AI can automate the quality assurance process and help pharma manufacturers in regulatory compliance. AI coupled with blockchain solutions can monitor cold chains for vaccine transports.

Pfizer, one of the top pharma companies in the world says that artificial intelligence can help them in predicting queries that regulators will raise after inspection. AI/ML analysis may also be able to improve the quality of regulatory submissions, says Boris Braylyan, Vice President and Head of Information Management at Pfizer (source).

Chemical Manufacturing Industry

AI speeds up research, substances analysis, chemical properties prediction, and discovery of new compounds. Advanced techniques like generative modeling further shorten the drug discovery process. Machine learning algorithms trained on generative AI can conduct quality checks to prevent contamination. Chemical manufacturing is carbon-intensive and not eco-friendly. AI can be deployed to analyze energy use patterns and suggest adjustments to reduce consumption to minimize the carbon footprint.

Aerospace

AI algorithms can create thousands of design permutations based on specified constraints and requirements. AI-driven simulations can predict how different materials and designs will perform under various conditions, reducing the need for physical prototypes and extensive testing.

Airbus, the commercial aircraft manufacturer, uses Artificial Intelligence for various use cases, from creating AI-based robotic assistants for space astronauts to developing self-piloted commercial aircraft using AI-enabled computer vision. Using AI in Aviation manufacturing companies in this space are developing solutions to cut aircraft aerodynamics prediction time.

Furniture Manufacturing

AI tools can study customer feedback and reviews and help manufacturers customize furniture designs as per the latest preferences and trends. AI improves demand forecasting, helping furniture manufacturers manage inventory more efficiently. AI optimizes logistics and delivery routes, ensuring timely and cost-effective delivery of products.

IKEA, the furniture manufacturing giant uses AI to optimize delivery. In its new 25,000 cubic meter distribution center in Tianjin, China, IKEA is testing AI-based Autonomous Mobile Robots to pick and pack 9,500 products. (source).

Transform your manufacturing processes with cutting-edge AI technologies!

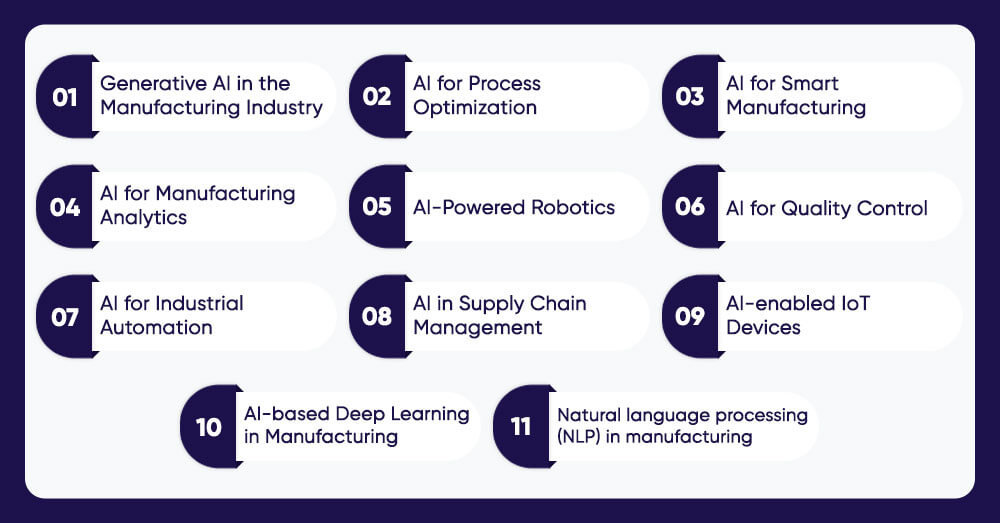

How is AI Used in Manufacturing? Top Use Cases

Gen AI is the most disruptive AI advancement. These are language models trained on billions of data sets. Gen AI resembles human-like interaction as a language model. Generative AI is primarily used for conversational purposes in manufacturing to initiate human-like chats with suppliers and customers.

It is also used for summarizing information in contractual documents. 27.1% of manufacturing companies surveyed by IDC (Report: The State of Manufacturing and Generative AI Adoption in Manufacturing Organizations) accepted investing in generative AI in 2023.

Top Generative AI Models Application in Manufacturing

| Gen AI Model | Application |

|---|---|

| Variational Autoencoders (VAEs) |

|

| Generative Adversarial Networks (GANs) |

|

| Long short-term Memory (LSTM) networks |

|

| Recurrent Neural Networks (RNNs) |

|

AI for Process Optimization

AI has impactful applications in the manufacturing industry’s process optimization. By analyzing historical process data, AI can identify parameters that influence manufacturing phases, processes, and quality. From anticipating quality issues, process malfunctions, causes of disruptions, and deviations from target parameters.

Reinforcement Learning to develop control strategies that maximize efficiency and quality.

Neural Networks for complex process control, where traditional methods are insufficient.

Smart Energy Management Systems that use AI to optimize energy usage.

Simulation and Optimization models to test different production scenarios

Route Optimization for logistics, reducing transportation costs and delivery times

Factory floor Optimization Layout in factories can be optimized using AI for space optimization and more efficient machinery placement

AI for Smart Manufacturing

Smart manufacturing combines the power of advanced technologies like AI, Machine learning, blockchain, Industrial IoT, and robotics to increase productivity, reduce manufacturing errors & delays, and ensure quality. Smart manufacturing also considers worker safety and deploys ways to improve worker life. Smart manufacturing also focuses on optimizing production levels based on inputs received from data analytics. AI-driven data analytics can predict market demand and guide manufacturers about production levels.

As per a report by Business Insider, the world’s leading chipmaker, Nvidia is using a custom AI model (ChipNeMo) to scale up its chip production process.

AI for Manufacturing Analytics

One major use of AI in manufacturing is data analytics. AI in manufacturing analytics has use cases varying from predictive analytics to supply chain route optimization. AI-enabled analytics can also predict raw material demand or workforce requirements in manufacturing plants by analyzing data from production channels, sales, and marketing.

The manufacturing analytics with IoT device sensors can detect anomalies in machines, and deteriorating performance signs, and predict downtime. It can accurately measure the mean time between failures (MTBF) or mean time to repair (MTTR). With such analytics, manufacturing can schedule preventive maintenance of equipment before it turns into a failure risk.

AI-Powered Robotics

AI-powered robots enable 24/7 factories. Robots can work without fatigue and therefore are prudent solutions to peak demand or sudden surges in workload. For example, with the use of AI-enabled autonomous robots in warehouses, manufacturers can reduce the workloads of warehouse employees. From sorting products to moving pallets, these robots use AI to evaluate the product category, understand weight, and move through obstacles in the warehouse without collisions.

- Collaborative Robots (Cobots) that work alongside humans, improving efficiency and safety.

- Autonomous Guided Vehicles (AGVs) for material handling and transport within manufacturing plants.

AI for Quality Control

AI’s application in quality control work by inspecting various stages of production and detecting deviations or defects using computer vision and imaging tech. For instance, AI-enabled image processors can detect defective parts of machinery, coating issues, fitting issues, welding issues, etc., especially in heavy machinery manufacturing. This reduces defect slippages that can happen in human-based visual inspections. AI can go into root cause analysis (RCA) by finding gaps or loopholes in standard operating procedures.

The Google Cloud Visual Inspection AI solution can detect anomalies and even the tiniest defects by using its ultra-high resolution images (up to 100M pixels) and advanced computer vision technology.

Such AI use for quality control is particularly beneficial for packaging and label inspection, Paint shop surface inspection, SoC packaging inspection in the semiconductor industry, and finding missing components (screw, spring, connector) in the electronic industry.

AI for Industrial Automation

Artificial intelligence (AI) technologies are opening up new opportunities, and making manufacturers more adaptable to changing market conditions. In industrial settings, AI is used for powerful 3D automation services to automate intricate designs with remarkable accuracy. For factory automation automates troubleshooting, service management, and anomaly identification. AI also automates warehouse processes improving logistics. AI also automates raw material order management by generating purchase requests based on demand predictions. CAD automation in manufacturing eases complex design tasks and reduces errors.

AI in Supply Chain Management

AI analyzes supply chains to detect and address potential roadblocks early. AI in the supply chain can optimize global logistics by rerouting transportation and rethinking warehouse operations. Its predictive power can help in anticipating geopolitical events, and market fluctuations to provide early warnings to create contingency plans. In November 2023, the Biden administration established the White House Council on Supply Chain Resilience while implying the development of safer AI solutions to monitor and respond to supply chain disruptions.

AI-enabled IoT Devices

AI-enabled IoT has many applications in the manufacturing industry. Healthcare device manufacturers embed sensors with AI in IoT wearables to monitor patient vitals. Smart thermostats, HVAC equipment, Smart ACs, and home appliances are other examples of AI and IoT convergence. Industrial Internet of Things (IIoT) with AI has extensive use cases. For example, smart thermostats can automatically control room temperatures. Smart ACs can automatically on/off by sensing the weather, or people in the room. An advanced example of IIoT with AI capabilities is GE’s latest locomotives, which are equipped with 250+ sensors with capabilities to collect 150,000 data points per minute.

AI-based Deep Learning in Manufacturing

AI-based deep learning reduces unplanned downtime by predicting equipment fails by analyzing historical and real-time machine data. Deep learning models can analyze images and detect defects in manufactured goods. Deep learning models can optimize energy consumption within manufacturing plants and improve sustainability by analyzing consumption patterns. AI systems can monitor worker activities to detect hazards and warn the managers.

Natural language processing (NLP) in manufacturing

Natural Language Processing (NLP) in manufacturing assists in global operations by translating communications instantly. NLP also enables interactive training manuals and eases workforce training in the manufacturing industry . NLP can be used to monitor employee feedback and based on it sentiment analysis can be done to understand job satisfaction in workers. NLP can also be used for condensing large texts into actionable insights.

Implement advanced AI Solutions in Your Manufacturing Processes

Get Quote Now! Get Quote Now!Ethical Considerations of AI in Manufacturing

Authors like Isaac Asimov and scholars like Norbert Wiener were among the first to explore ethical dilemmas posed by AI. Asimov's Three Laws of Robotics laid foundational ethical principles for human-robot interactions. These pioneers foresaw issues such as the potential loss of human control over technology, ethical dilemmas in decision-making by AI systems, and societal impacts of automation. For manufacturing companies, this raises fundamental questions about balancing technological innovation with ethical considerations.

The deployment of AI in manufacturing raises significant ethical concerns. These include safety (both physical and cybersecurity), ethical decision-making by AI systems, bias in algorithms, social implications of job displacement, and the overall trustworthiness of AI-driven operations.

Policymakers, government agencies, technology leaders, and scientists globally are engaged in discussions about how to regulate and ensure the responsible development and deployment of AI technologies. There is a growing consensus on the necessity for establishing clear ethical guidelines or a code of ethics specific to AI in manufacturing and industrial operations. This framework would aim to ensure that AI systems are developed and used in ways that are safe, ethical, unbiased, socially responsible, and trustworthy.

The Future of AI and Its Impact on Manufacturing Jobs

Although AI has been around for decades now, its powerful and transforming applications in various industries have recently spurred owing to multiple factors such as:

- Increase in adoption and reduction in implementation resistance from conservative management

- Breakthrough launches in generative AI like ChatGPT

- Convergence of AI with advanced technologies like Blockchain, IoT, Big Data, etc.

- Advancements in computing power and advanced GPUs

- Improved AI algorithms, deep neural networks, and ML

- Establishment of Regulatory frameworks for AI usage

As per McKinsey, Manufacturers that have applied AI in industrial processing plants have reported a 10 to 15% increase in production and a 4 to 5 percent increase in EBITA. With the increased adoption of AI, 40% of manufacturing managers surveyed by the Manufacturing Leadership Council reveal that they expect their manufacturing plants and factories to go fully autonomous by 2030. However, employees will still play an important role in operations.

The World Economic Forum Report on Implications of AI on Manufacturing Workers reveals that AI will liberate factory workers from hard toil. AI robots will perform repetitive and mundane tasks and reduce jobs that involve routine assembly line work. AI adoption will lead to new job opportunities focused on process improvement, and advanced data analytics.

AI and manufacturing are a perfect match. The fusion of AI in manufacturing is a wave that will transform the industry.

Conclusion

The implementation of AI technologies and systems improves manufacturing efficiency, ensures worker safety, enhances product output quality, and expedites floor processes. AI also improves the level of sustainable practices and provides insights for strategic decision-making to manufacturers. The benefits of AI deployment in manufacturing extend from workers and management to customers, suppliers, and all other stakeholders.

If you want to implement AI-based applications for your manufacturing units, you will need a reliable IT partner who understands the intricacies of designing, developing, and deploying AI software solutions for the manufacturing industry. X-Byte has expertise in developing futuristic manufacturing industry AI solutions.

Frequently Asked Questions

-

What are the top Challenges of Implementing

AI in Manufacturing?

Data issues, governance issues, replacement of legacy systems to accommodate AI, algorithm bias, poor AI training, worker resistance and fear, conservative C-Suite management, and high costs of implementing AI in manufacturing are some of the top challenges of implementing AI in manufacturing. ROI of AI in manufacturing is also a concern. CEOs have been hesitant and unsure about the return on investment of AI implementation in their manufacturing plants.

-

How AI-enabled AR/VR can be used for

employee training in manufacturing?

AI-enabled AR/VR can be used for employee training in manufacturing by providing immersive, interactive, and highly safe training environments. AR/VR can create detailed simulations of the manufacturing floor, allowing trainers to teach new employees without risks. Trainees can practice safety protocols in a controlled virtual environment.

-

How to get started with AI in manufacturing?

Start with Identifying specific areas where AI can add immediate value to your manufacturing business. Decide where you need automation and analytics, i.e. predictive maintenance, quality control, supply chain, or all of these. Partner with an AI development company that understands both AI technology and manufacturing needs. Invest in training for your team to build AI literacy and skills. Finally, ensure a scalable infrastructure and continuously monitor and optimize AI systems to adapt to evolving manufacturing demands.