-

solutinos

-

Hire

Frontend Developer

Backend Developer

-

NodeJS Developer

-

Java Developer

-

Django Developer

-

Spring Boot Developer

-

Python Developer

-

Golang Developer

-

Ruby on Rails Developer

-

Laravel Developer

-

.NET Developer

Technology

-

Flutter Developer

-

React Native Developer

-

Xamarin Developer

-

Kotlin Developer

-

Cross-Platform Developer

-

Swift Developer

-

MongoDB Developer

-

C Developer

-

Smart Contract Developers

Cloud

-

-

Services

Mobile Development

Web Development

- Work

-

Multi Services App

-

Food Delivery App

-

Grocery Delivery App

-

Taxi Cab Booking App

-

Multi Services App

-

OTT Platform APP

-

Social Media APP

-

Freelance Service App

-

Car Rental App

-

Medicine Delivery App

-

Liquor Delivery App

-

Sports Betting App

-

Online Coupon App

-

eLearning App

-

Logistics & Transportation App

-

Courier Delivery App

-

On-Demand Real Estate App

-

E-Wallet APP

-

Online Dating App

-

Handyman Services App

-

-

Process

-

Company

Quick Summary : Wholesalers purchase products from the producer or manufacturer and sell them to dealers and other businesses. However, they experience several issues, such as increased operational costs, inventory management, appropriate storage space, and other concerns related to consumer demands.

.jpg)

In our previous post, we discussed the concept of drop shipping in detail. We understood what it means, how it operates, the challenges, and their solutions. If drop shipping was all about not having to maintain a warehouse or real estate, what we will discuss today is entirely the opposite.

This post will look at another exciting business model significant to the retail and e-commerce industries. It is an integral part of the order fulfillment process, and the entire chain of consumerism would crumble if you were to remove this aspect from the process.

Yes, it is the process we call wholesaling and warehousing.

From a layman’s perspective, wholesaling and warehousing are concepts we tend to overlook as consumers don’t generally consider packaging and deliveries once their product reaches their home. But the ballgame is entirely different from a business owner's perspective.

People involved in wholesaling and warehousing are the bridges between brands and consumers. Their functionality and ethics depend on the reputation of a brand or marketplace they are associated with.

If you think about it, a store is just an intermediary that fetches consumers their preferred products. Actual and indirect transactions happen between wholesalers/manufacturers and consumers.

Without a proper wholesaling and warehousing system or model, businesses couldn’t profit or sustain themselves.

As such inevitable aspects of business functioning, let’s take time to understand this business model, how it is different, how it is interdependent, its challenges, and some credible solutions.

What Are Wholesaling And Warehousing In Retail and Ecommerce Businesses?

Firstly, both are distinct concepts that we should understand individually. To understand warehousing, let’s first get to know wholesaling.

Wholesaling In Retail and Ecommerce

The opposite of retailing is wholesaling. If retailing is all about selling a product to a consumer, wholesaling is selling a product to a middleman who sells it to a customer. The middleman invests in setting up a store (online, offline, or both), building a brand for it, advertising, recruiting salespersons, and more to ensure the smooth operation of the business.

The sole purpose of a wholesaler is to consistently supply products or goods to the intermediary business and ensure that consumers' demands are always met.

Moreover, retailing is a business-to-consumer concept, whereas wholesale is a business-to-business concept.

Warehousing

Warehousing is an aspect of wholesaling that provides real estate for the process. It is the concept of storing products and goods so wholesalers can supply them to different channels, stores, and vendors as and when required.

Warehousing is crucial because it is a centralized unit that ensures

- Adequate manufacturing of goods

- Appropriate storage of good

- Timely delivery of goods.

estimate the manufacturing volume for a particular period. A well-maintained warehouse can prove to be cost-effective and productive for manufacturers.

Different types of warehouses cater to the distinct needs of private, public, and government initiatives.

For our purpose, we will stick to warehousing associated with retail and ecommerce businesses.

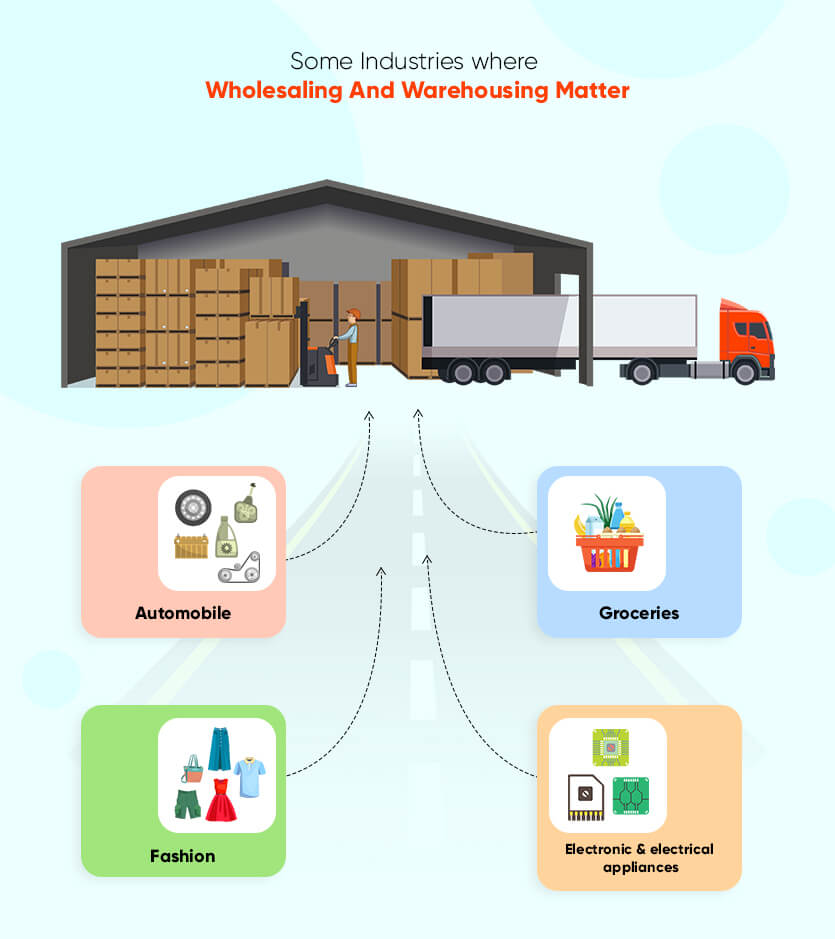

Some Industries where Wholesaling And Warehousing Matter

- Automobile – from finished cars and vehicles to spare parts

- Groceries – raw materials and ingredients to instant and ready-to-eat products

- Fashion – apparel and clothing

- Electronic and electrical appliances – finished gadgets to materials like superconductors, chipsets, and more

Leverage our expertise in advanced solutions and get wholesaling and warehousing platforms with our expertise in the field!

Connect with Us Now Connect with Us NowChallenges In Wholesaling And Warehousing

Wholesaling and warehousing are behemoth concepts, and the minimum volume we talk about starts from 1000 (depending on industries). When such massive volumes are involved, challenges are bound to be plentiful. From liaisons with vendors and manufacturers to proper inventory management, many hurdles hinder the operations of wholesale and warehouse businesses. A blunder would be when one of your employees jumbles the numbers of two particular products and wrongly notes them down. This could cost you a price as, based on the numbers, you manufacture more of a product than you already have in excess.

Offline Tracking Systems

Where you don’t have a proper online point-of-sale mechanism in place to take care of your inventory and its associated requirements

Real-world Scenario: You still rely on manual stocktaking of products and maintain ledgers and heavy files to process them.

Redundant Tasks

Where you have dedicated manpower working on purchasing, reordering, invoicing, financing, and similar tasks.

Real-world scenario: Without an automated system in place, you are limiting the potential of your manpower by indulging them in redundant tasks.

Fraud Orders

These are where you pack and dispatch high-stake orders only to realize they are fraud or fake orders with no purchasing intention in the first place.

Real-world scenario: You dispatch an expensive laptop to one of the fake buyers online, who rejects it. Apart from the expenses involved in shipping and getting it back, you also gamble on the quality of the product in transit and its probable chances of getting damaged.

Transactional Processes

The problems are primarily the currencies involved in transactions, distinguishing between retail and wholesale prices, discounts or price breaks for bulk orders, personalized pricing based on rapport, and more.

Real-world Scenario: You could incur losses when a payment is made in a foreign currency, and the value is reduced because of the volatile market.

Customer Segmentation

Where you find it difficult to segment your buyers according to their frequency of purchases, types of goods purchased, and more

Real-world Scenario: You quote the same price for a business that has been doing business with you for years and one of your most recent associations.

Supply-chain And Logistics

Causing delays in deliveries and shipping, poor tracking of shipments, poor coordination between vendors, and more

Real-world Scenario: Delays in packing and dispatching orders with special delivery date requests, additional payment of exclusive shipping charges, and other factors result in disappointed customers.

How To Fix The Challenges In Wholesaling And Warehousing

.jpg)

Inventory Management – to give you a complete holistic perspective of all the items in your inventory. From their quantities and date of ordering to notes on next batch reordering details to shipment details, get everything on one screen through a proper digital inventory management system.

Order and Fulfillment Management: automate the process of packing and shipping products to businesses and monitor shipment-in-transit from a dashboard. Get precise estimated date of delivery details and more crucial information regarding order fulfillment.

Relationship Management: Replace conventional and generic emails with personalized ones that address specific customer behavior, requirements, and attributes. From acknowledgment to gratitude messages, send and maintain ideal relationships with vendors and businesses.

Multichannel Orders – streamline online and offline orders in one space while distinguishing them regarding order fulfillment. Segregate orders according to sources, prioritize orders, distinguish prices, and do more with multichannel management systems.

Unified POS—Every wholesale and warehouse business needs a centralized POS to keep track of its comprehensive inventory across boundaries. With a unified POS, you can move products from excess produce regions to the ones in demand and vice versa.

Logistics Management—Implement a logistic management system to solve the last piece of the supply-chain mechanism puzzle. This would allow businesses to track goods better, pack fragile and hard products accordingly, prefer appropriate shipping techniques, and more.

Case Study

FedEx is one of the world’s largest delivery services. It has close to 425,000 employees and serves over 220 countries. In 2018, FedEx reported revenue of $65.4bn. It has complex warehousing policies and processes to ensure logistics reach on time regardless of the location.

FedEx believes a warehouse is crucial for a business’s reputation, flexibility, and profitability. Businesses should understand different and complex processes happening across a warehouse to optimize their services and delivery. To facilitate this, FedEx ensures it:

Offers shared and dedicated warehouse spaces

Develop or acquire new warehouses

Implements ways to optimize and manage warehouse staffing

Design and build distribution centers and more

Transform the data warehousing processes by automating the management with advanced solutions.

Future of Warehousing And Wholesaling

Some of the above solutions are the benchmarks businesses will set in the coming months. Conventional and analog ways of maintaining warehouses will become obsolete, forcing companies to adopt tech in their operating strategies.

More sensible organizations would understand the importance of what a solid tech infrastructure can do for their businesses. They would invest in robotics, artificial intelligence, machine learning, data analytics, industrial automation, the Internet of Things to replenish goods, and more.

A layer of technology will turn an otherwise redundant technology into a happening space.

The coming years are going to be exciting in this industry, and regardless of the market you are operating in, you will face the challenges we have seen so far.

The ideal solution is to go digital with your business and get specific management systems or enterprise applications built for your wholesale and warehouse business. We implement business intelligence tools in your application so you can automate most of the complex operations processes.

Contact us to get a solid application tailored for your business.